The patented Acti-FeedTM technology simplifies embroidery, allows higher embroidery speeds in perfect stitch quality with every type of thread and simplifies the production of special effects. How exactly? Read more:

Before the invention of the Acti-FeedTM system, the thread was also drawn into a clamping system with thread brakes (passive thread feed) on our embroidery machines. This regulated pressure and resistance of the thread. Unfortunately not automatically. Instead, the thread tension had to be adjusted manually, depending on the thickness of the material to be embroidered. This greatly influenced the embroidery quality and lead to different looks of the embroidery with different machine operators. It was also a frequent source of errors.

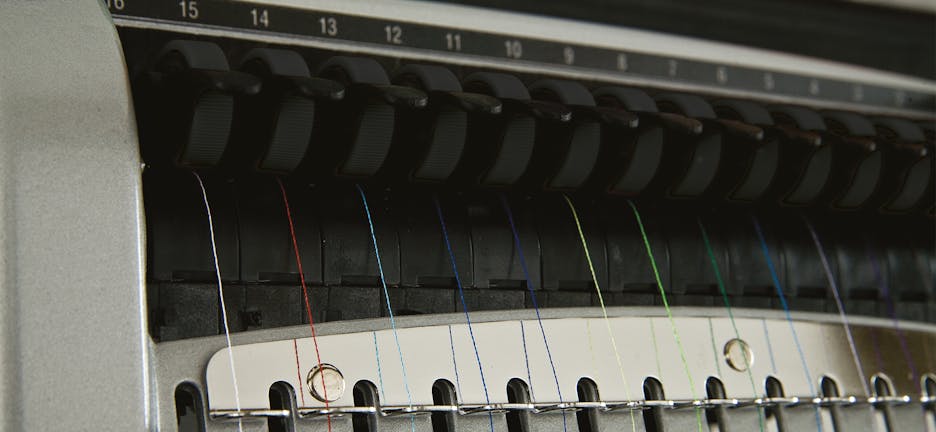

However, the patented Acti-FeedTM system is a positive thread feed. This means that the thread is supplied by the Acti-FeedTM unit and not pulled by a brake, as is the case with conventional embroidery machines. As a result, the thread has little or no tension when the machine runs. Using a sensor and complex algorithms, the embroidery machine calculates the perfect amount of thread for each stitch and continuously adapts to the material being embroidered. It can also embroider across seams and other uneven surfaces without any problems and without affecting the embroidery quality. Thanks to this technology, the number of thread breaks is drastically reduced despite a much higher embroidery speed. It also simplifies quality control and enables the exact reproduction of jobs. This is because the embroidery will always look the same, because nobody can manipulate the thread brakes and thus influence the look of the embroidery.

Find out which advantages the Melco EMT16X has in store for you in addition to Acti-FeedTM.

Learn how we can help you meet the challenges of your business with our tailor made solutions.